When it comes to interior design, literally every element, no matter how small, plays through the aesthetic value and ambiance created in the space. The frames of doors, too, do not lag behind in playing their role of setting the tone for the character of the room. Traditionally, they were crafted from wood and have been majorly prone to warping, rotting, and requiring constant maintenance. Not until a revolutionary material changed the game entirely: WPC, or Wood-Plastic Composite.

Besides providing great looks and being eco-friendly, WPC door frames are also excellent in terms of functionality and performance. This means that the uniqueness of WPC makes it fit for application in a wide array of uses.

What is WPC?

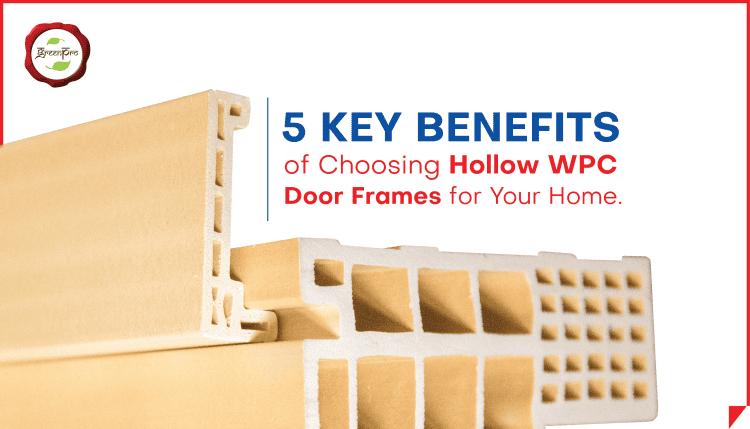

WPC is a new generation composite material engineered through the blending of wood fiber or flour with thermoplastic resins. The mix creates a product that easily identifies with the look and feel of wood but has the strength, toughness, and easy-care characteristics of plastics. Resulting WPC door frames, thus, exude an amalgamation of aesthetic appeal, functionality, and sustainability.

Durability Unbeaten: WPC door frames are extremely durable. Resistant to damp, termites, and warping, they retain their shape intact even in adverse conditions. Say goodbye to the frustrations of swollen or cracked door frames.

Low Maintenance: WPC frames, unlike their wood counterparts, require very minimal maintenance. The material used is fade-, chip-, and peel-resistant; it looks great for years. No more repainting or staining!

Eco-Friendly: WPC material is produced from recycled wood and plastic wastes, making it eco-friendly. Therefore, using WPC door frames helps reduce deforestation and landfill wastes, thereby impacting the environment.

Design Flexibility: WPC gives utmost design flexibility. It comes in a wide range of colors, finishes, and profiles, thus allowing you to match your door frames with any style—classic or contemporary—with much ease.

Cost-Effective Solution: Though its initial investment may be a bit more than the conventional wooden frames, its long life and almost negligible maintenance cost make WPC very cost-effective in the long run.

Performance & resistance in Challenging Environments

Moisture Resistant: WPC door frames are not affected by moisture and can be used in any application from high humidity areas like bathrooms, kitchens to coastal homes. No more concerns about swelling, warping and black mold!

Resistance to termites and insects: Termites always find a way around wood, but not on wooden decks. This mould-resistant property gives WPC an inbuilt quality that will help ensure that your home remains fungus and termite-free ensuring the structural integrity of your house.

Fire Resistance: WPC door frames are not fireproof; real wood is worst on this account, but definitely these new type of frames are better that most of the wooden doors and add to your family safety.

Sound Insulation: The dense composition of WPC means that it is better at muffling the sound and creates a much quieter, tranquil living environment.

Elevate Your Interior Design

WPC door frames provide a canvas for your design creativity. Their clean lines and modern aesthetic can elevate any space. Whether you’re designing a minimalist living room, a luxurious bedroom, or a functional kitchen, WPC door frames can seamlessly integrate into your vision. Imagine a bathroom where moisture-resistant WPC frames create a spa-like ambiance. Or a contemporary kitchen where sleek, white WPC frames complement stainless steel appliances. The possibilities are endless.

Installation and Care

Installing WPC door frames is similar to traditional wooden frames, but with added ease. They can be cut, drilled, and nailed without compromising their structural integrity. Regular cleaning with mild soap and water is sufficient to maintain their beauty. Moreover, their smooth surface provides an excellent base for painting, staining, or laminating, allowing for complete customization to match your interior design preferences.

Cost-Benefit

Though the initial cost may be a little more for WPC door frames compared to traditional wood frames, the long-term benefits offset the initial investment. Notice the following factors. Durability: WPC frames are long-lasting, thus no frequent repairs or replacement needed.

Maintenance: No maintenance requirement saves time and money invested in the same.

WPC door frames are versatile, sustainable, long-lasting, and stylish ways to change the strategy of building used on traditional wood door frames. One of the major factors that makes them so appealing to both house owners and builders is their ability to be versatile, low maintenance, and offer improved performance. With ever-growing demands for green, high-performance building materials, WPC door frames stay ahead as the premier choice in building fine and functional living spaces.

Embrace revolution of interior design with WPC door frames and feel the change. WPC is outstanding due to its durability, low maintenance cost, and eco-friendliness in modern homes and commercial spaces.