Architecture has passed through a transformation in door frame design because these structures now maintain crucial roles in interior aesthetics. The contemporary door frame design experience a revival through the convergence of modern materials and advanced design aesthetics which produce functional elements suitable for contemporary infrastructures. Modern architectural trends show that every architectural component now needs to function as well as serve aesthetic functions.

Clean lines and subtle profiles dominate current door frame design trends as one of its primary movements. Modern interior schemes find this style to be extremely popular because it delivers an unobtrusive elegant appearance that integrates effectively with multiple design schemes. The modern design preference of architects and designers involves using flush-mounted frames which match wall surfaces for a sophisticated appropriate appearance. People looking for contemporary design choices find such frames appealing.

Smart technology integration within door frames shows itself as a major current development. Technological advances result in contemporary door frames that include built-in sensors with electronic locking mechanisms as well as lighting systems. The intelligent security features in door frames provide better protection and deliver comfort and wealth to various property types. Modern advanced systems utilize climate control sensors that check air flow patterns surrounding doors to ensure proper indoor room temperature.

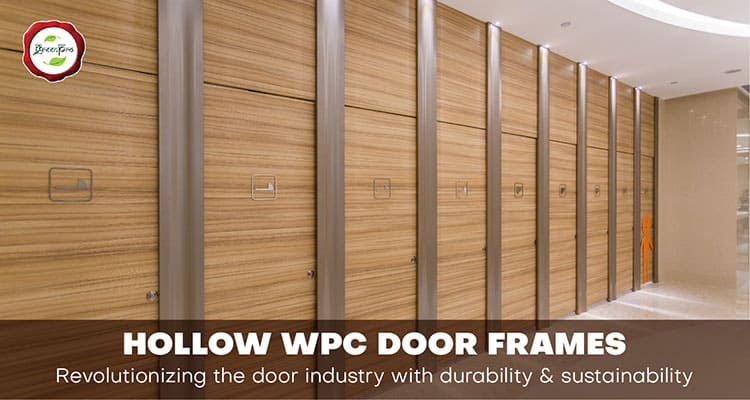

WPC (Wood Plastic Composite) leads as the key material innovation which shapes modern door frame advancements. The new commercial material blends wood aesthetic with impressive durability together with sustainability features. The durability of WPC frames consists of high resistance to moisture damage and termites along with weather conditions yet they need little care. Material designers seek WPC frames because their ability to replicate different textures and finishes enables designers to fulfill particular aesthetic needs without sacrificing durability.

Door frame color patterns have experienced substantial changes throughout times. White and wooden door frame styles continue their traditional appeal yet innovative alternative colors emerge as architectural design elements which emphasize door frames as unique components. Door frames in matte black have become increasingly fashionable because they create powerful visual contrasts with light-colored walls which results in dramatic effects. Modern spaces benefit from sophisticated and industrial aesthetic because brushed steel and bronze metallic finishes are used in door frames.

Door frame design now prioritizes customer variations as a fundamental aspect. The current market provides designers with various customization features which extend to dimensions and profiles as well as finish selection and integrated hardware specification. Architects and homeowners can develop exclusive functional solutions that represent their concepts without compromising requirements because of this design versatility. Manufacturers create personalized design solutions by implementing special angles that join frame corners while integrating unique profile designs and customizable built-in source lighting for door frame transformation.

Increasing awareness about the environment drives new design trends which affect door frame production. WPC sustainable materials represent only a fraction of eco-friendly manufacturing strategies that the industry now applies throughout its energy-efficient processes. Modern frames integrate better insulation functions and weatherproofing elements which enhance building energy efficiency. Sustainable intentions in design create new value without diminishing contemporary style in design.

These days larger door openings as well as floor-to-ceiling doors influence the way frame manufacturers design their products. Contemporary frame engineering now focuses on integrating the strong support of large heavy door systems with fashionable designs. Frame reinforcement systems and mounting inventions now withstand elevated loads because developers focused on designs that keep their attractive appearance. Modern buildings alongside luxurious private homes use such solutions for creating dramatic entrances.

As we look to the future, the integration of technology and sustainability with aesthetic appeal will continue to drive innovations in door frame design. The focus will likely remain on creating solutions that not only look beautiful but also contribute to the overall functionality and efficiency of buildings. This evolution in door frame design reflects our changing needs and expectations for the spaces we inhabit, whether at home or work.